HydroFLOW Neutralizes Bacteria, Algae, and Biofilm in Cooling Towers, Hot Water Boilers, Heat Exchangers and related Equipment.

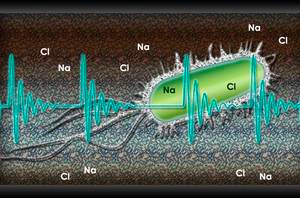

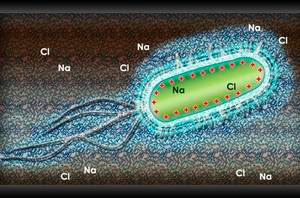

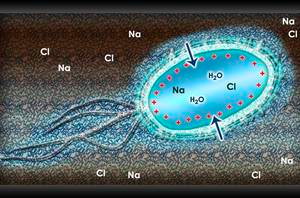

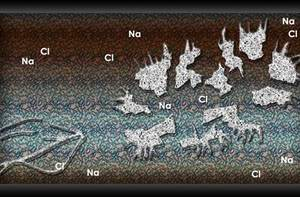

Hydropath technology can deactivate bacteria and algae without the use of chemical disinfectants. It does this by using an electric charge and the phenomenon of osmosis to force water into bacteria and algae, disrupting their natural functions and bursting them. The HydroFLOW signal causes biofilm to dislodge from pipes and equipment surfaces, and are easily filtered out of the water system. The frequency causes a bacterium to form a hydration layer of pure water around the cell. Osmosis forces water into the bacteria, creating osmotic pressure, which ruptures the cell membrane and prevents the cell from reproducing or will perish.

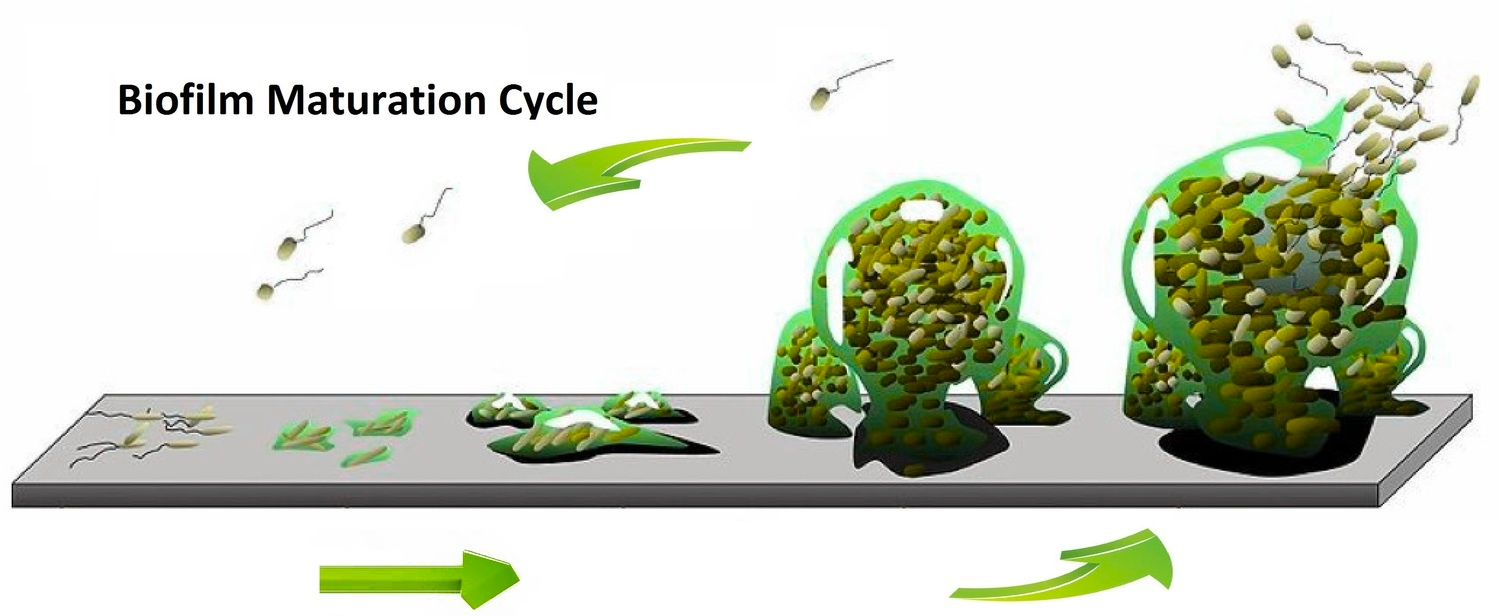

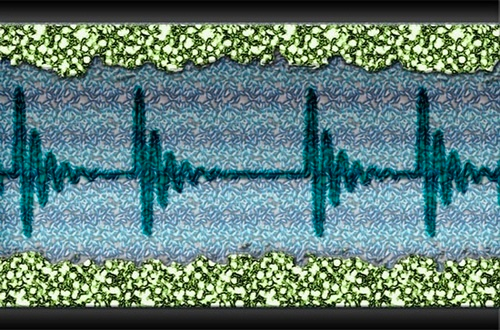

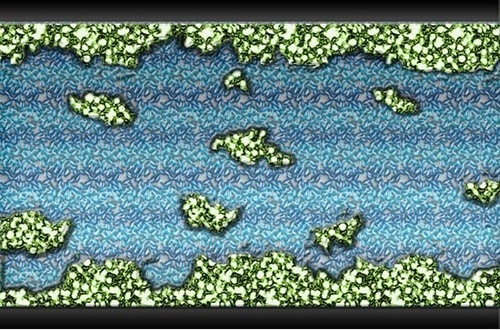

The Hydropath signal emanates in both directions of a water line, using the fluid to carry the signal. The sustained 150 kHz frequency prevents hard scale from forming and disrupts the bacteria and/or algae clinging to the rough inner surface, gradually releasing the biofilm over time.

Contact Us to Schedule a Risk-Free Evaluation, or

To Learn More about HydroFLOW for biofilm control and removal.

Download Lab Reports and Case studies for Biological Control on our Resources Page

Based on over twenty-five years of experience, the patented HydroFLOW technology works with all equipment and piping systems, including:

- Cooling towers

- Hot Water Boilers

- Heat Exchangers

- Water and Wastewater Piping

- Commercial pools

- Wells: water, injection, oil and gas

- Pumps

Installed on the exterior of any piping system or pipe material, the HydroFLOW™ device employs a ferrite ring to induce an oscillating 150 kHz frequency that penetrates the pipe wall and travels both upstream and downstream from the point of installation. The water within the piping system, acts as a conduit to propagate the signal throughout the system, conditioning the water, whether it is moving or stationary. Testing has proven that the HydroFLOW™ signal is more efficient and effective than similar water conditioning technologies.

HydroFLOW technology deactivates bacteria and algae without the use of chemical disinfectants, such as Legionella. The HydroFLOW signal deploys an electric charge and utilizes the process of osmosis to force water into bacteria and algae, disrupting their natural functions and rupturing their cell walls. The radio frequency signal causes a hydration layer of pure water to form around a bacterium or algae cell. Osmotic pressure pulls water into the cell, rupturing the membrane and preventing it from reproducing. The HydroFLOW signal also causes biofilm to dislodge from pipe and equipment surfaces, which is then easily filtered out of the water system.

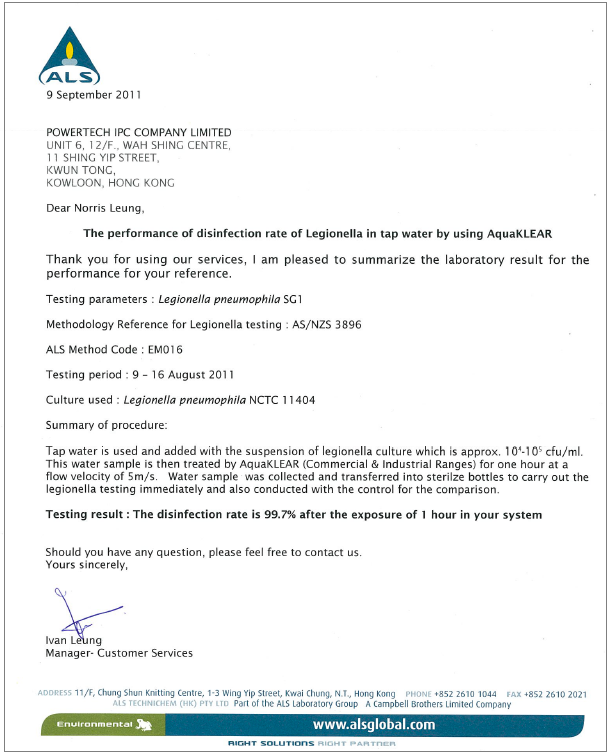

In laboratory testing, HydroFLOW has demonstrated a 99.7% kill rate in recirculating systems after 1 hour of exposure to the HydroFLOW signal

HydroFLOW units are available to fit pipe sizes ranging from 1.5” to 72” outside diameter.

Removal of Biofilm

Common biological problems with HydroFLOW™ solutions:

- Microbial Induced Corrosion (MIC). Slow-moving or standing waters are prone to the development of bacteria, particularly SRBs, since these areas are not well penetrated by disinfectant chemicals, and flow turbulence is not available to dislodge biofilm. The HydroFLOW signal is propagated throughout a piping system, regardless of the flow velocity, penetrating and protecting slow-moving or standing channels from MIC.

- Legionella: HydroFLOW protects cooling towers against Legionella, even when cooling demand is low.

- Loss of heat transfer efficiency: Biofilm acts as insulation, lowering the heat transfer efficiency of the chiller tubes. The HydroFLOW signal agitates the biofilm, causing it to detach.

150 kHz Frequency that extends through the water line

Pure water forms around the bacterium

Bacteria Ruptures and the cytoplasm disperses

Osmosis is induced and the cell expands

Results:

HydroFLOW neutralizes bacteria, including Legionella in flowing water, and increases clarity due to improved filtration

Reduce Chlorine use by 50-75% and removes the Chloramine Odor. Improves the performance of chlorine and reduces the amount required to maintain low bacteria and algae levels.

HydroFLOW improves water clarity and extends the life of the filtration system

Legionella Controlled without Chemicals

The water quality of a cooling tower system at a commercial facility in China continued to operate below standards for the first half year of 2008. Chemicals were changed frequently but failed to achieve a desired result. When Hydropath technology was used without the adding chemicals, the total bacteria count decreased to below 1,000CFU/mil and Legionella was no longer detected.

Legionella Control

The Legionella count in a cooling tower system at a shopping mall exceeded the specified concentration limits despite regular chemical dosing applications. When Hydropath technology was applied, the bacteria count was maintained below action limits after scheduled testing.

Water Park: 80% Water and Chemical Cost Reduction

The water park maintains improved quality water with the continued use of the HydroFLOW units. In addition to cost reductions for Water, Chlorine, Acid, and Natural Gas, the staff experienced an increase in the clarity of the pool water and a reduction in chlorine odor (chloramines).

Honda Manufacturing Facility Cooling Towers

Honda manufacturing in Japan experienced suboptimal results from regular chemical treatments and performed a test of Hydropath technology in several areas of their facility, including heat exchangers, cooling towers and oil coolers. The results after 108 days were that scale had not formed and old scale was removed from the use of Hydropath without chemicals. Algae and Legionella pneumophila were controlled. Honda installed several Hydropath units throughout their plant with continued success.

Bacteria, Scale and Corrosion Control with Reduced Chemical Use

A commercial building operator in Hawaii initiated a four month test of HydroFLOW technology for the purpose of evaluating the reduction of chemical use for bacteria, scale and corrosion control in three cooling towers. HydroFLOWs were installed on the cooling towers after baseline analysis was performed. During the staged test, chemical additives were systematically reduced to provide comparison of operating efficiencies of the HydroFLOW units. The result was a return on investment in less than four months and long term savings of more than $1 million in operating costs.

Water Impoundment Recirculation for Bacteria Control

Water that is stored in high volume reserve pits that are susceptible to bacteria growth, especially sulfate reducing bacteria (SRB) that are anaerobic and must be removed before use due to hydrogen sulfide byproducts that are toxic to humans and corrode steel piping and infrastructure. HydroFLOW technology is used to recirculate the water in pits as an alternative to chlorine dioxide (ClO2) which causes iron to precipitate from solution and becomes a host for SRB colonies. HydroFLOW provided consistent bacteria neutralization between 88%-97% through recirculation.